Grease and water: solutions for public authorities and ERP

Grease and wastewater management is a crucial issue for local authorities and public facilities such as hospitals, schools, nursing homes and administrative buildings. These structures produce large quantities of water laden with grease, organic matter and various pollutants, which can cause environmental, health and technical problems.

It is therefore essential to treat this water before it is discharged into the sewer system or the natural environment, in order to comply with current standards and preserve water quality.

What are the main issues involved in water treatment and regulation for local authorities?

Wastewater from local authorities and ERP facilities has special characteristics, which call for specific treatment solutions. These characteristics include :

- Blocked pipes Grease build-up in pipes, particularly in water from kitchens, restaurants and canteens, can cause blockages and overflows, leading to odor nuisance, health risks and high repair costs.

- Water pollutionx: Discharge of untreated wastewater into rivers and lakes can pollute the environment and harm flora and fauna.

Variability of flows and pollutant loadsThese variations can lead to hydraulic overloads in the system. These variations can lead to hydraulic overloads in the network, and must be regulated as close as possible to the source.

What regulations apply?

The treatment of wastewater and grease is governed by a number of European, national and local regulations.

The sanitation regulations of the local authority, agglomeration or urban community require pretreatment of these effluents before they are discharged to the treatment plant. For example, the regulations of the Hauts-de-Seine departmental wastewater treatment service stipulate that “non-domestic effluent must … be free of floating, depositable or precipitable matter likely, directly or indirectly after mixing with other effluent, to interfere with the proper operation of the works, to interfere with the operation or final disposal of sludge from the treatment works (particularly grease) or to develop gases that are harmful or inconvenient for those working in the network”. Other regulations may apply, in particular for classified installations subject to authorization.

Grease traps and separators must comply with European standard 1825, parts 1 and 2:

- EN 1825-1 Principles for design, performance and testing, marking and quality control.

- EN 1825-2 Nominal size selection, installation, service and maintenance.

Products must also comply with the French standard NFP 16-500-1/CNnational supplement to NF EN 1825-1.

Note: EN1825 applies to separators designed to separate fats and oils of vegetable and animal origin from wastewater (with the exception of wastewater containing faecal matter) by gravity and without external energy input.

Solutions provided by Saint Dizier Environnement

Our product offering covers a wide range of applications for local authorities and ERP (schools, hospitals, EHPAD, public establishments, etc.).

- Grease traps in coated steel, stainless steel, polyethylene or polyester composite

- Grease and starch separators in coated steel, stainless steel, polyethylene or polyester composite

- Compact under-sink units in stainless steel or polyethylene

- Grease traps with biological treatment to reduce residual grease in stainless steel

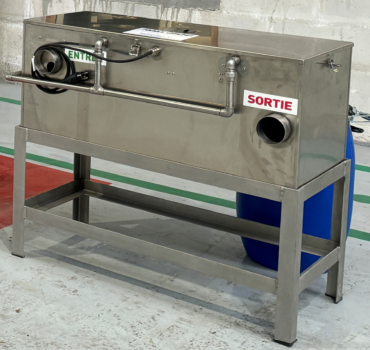

- Innovative GRECUP-type grease separators in stainless steel, enabling grease to be recovered and recycled for a wide range of applications: hotels, restaurants, fast-food outlets, schools, rotisseries, etc., as well as on liners, ships and cargo ships with the marine version.

KALIO model with polyethylene socket

SAMBRE model in stainless steel

GRECUP model, with grease recovery

We can also offer you several services:

- Audit your installation

- Sizing study

- Installation and commissioning of equipment

- Operating assistance (contracts with monitoring, control and follow-up frequencies)

- Design and manufacture custom solutions to meet your exact requirements, as illustrated below for a fast-food restaurant:

Custom design and on-site assembly by our construction department

Customized design of a water pre-treatment system for a 20,000 meals/day central kitchen, with the implementation of a stainless steel aerated and scraped degreaser.

Consult our product ranges or contact us for a personalized proposal.